Salford BBI maintains a commitment to providing a variety of granular material application solutions expressly created to improve the financial performance of all Salford BBI customers. BBI Spreaders was acquired by Salford Group in 2014 and is now a part of the Salford Group lineup of tillage and application equipment.

Hydraulic Fertilizer/Lime Variable Rate Precision Application Spreaders

10′ -12′ BBI Tandem Axle MagnaSpread

Available in mild steel, 409 stainless steel, and 304 stainless steel. ISO bus ready spreaders can be operated with your current ISO Variable Rate Terminal (JD2630, Case Pro700, and others)

Standard BBI MagnaSpread Spreader Options

- UHMW bearing backers keep bearings clean, giving longer life and fewer failures.

- Proprietary MagnaSpread system delivers a wider, flatter, more consistent pattern.

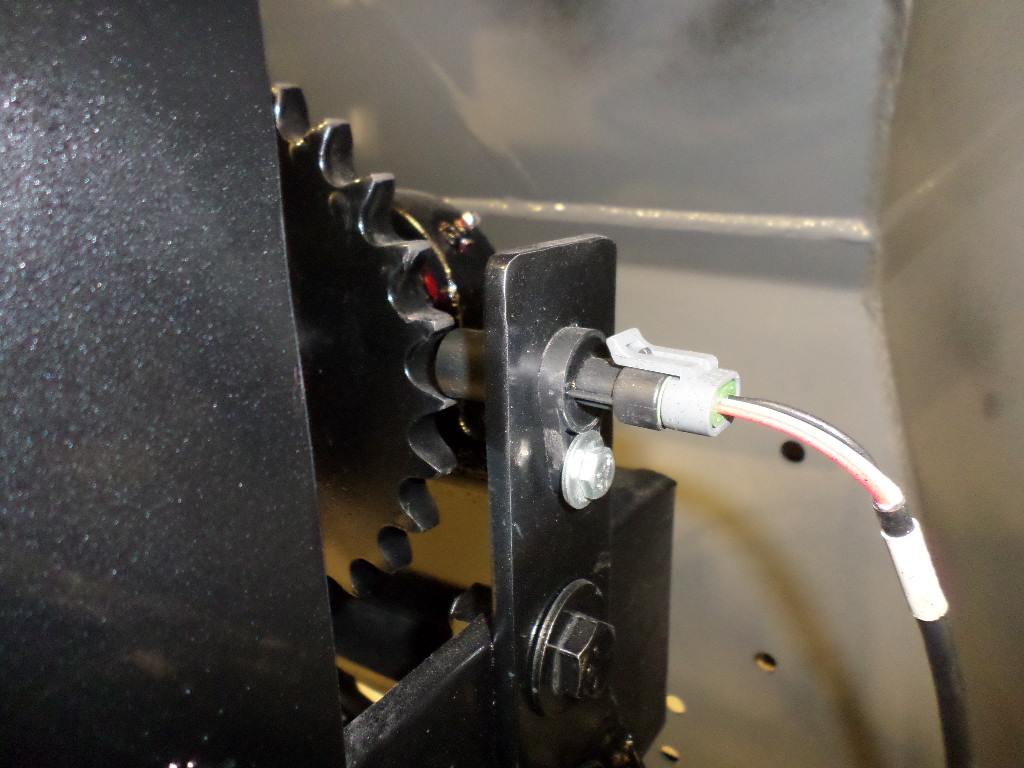

- Dual Rack and Pinion Gate prevent jams.

- Overhead spinner motors are ABOVE the chemical resulting in extended motor life.

- Pull with a tractor; no need to maintain a dedicated chassis and power train.

- Variable or straight rate compatibility.

- UHMW precision-cut comb cover prevents spillage of fertilizer and potential streaking in the field.

- Flotation tires and wider swaths minimize compaction.

- Standard chain option spreads lime up to 2 tons per acre @ 14mph with a 60′ swath.

- Spreads fertilizer in 80′ swaths.

14′ -16′ BBI Tandem Axle MagnaSpread

Hydraulic Fertilizer/Lime Variable Rate Precision Application Spreader. Available in mild steel, 409 stainless steel, and 304 stainless steel. ISO Bus Ready Spreaders can be operated with your current ISO Variable Rate Terminal (JD2630, Case Pro700, and others)

Standard BBI MagnaSpread Spreader Options

- UHMW bearing backers keep bearings clean, giving longer life and fewer failures

- MagnaSpread System delivers a wider, flatter, more consistent pattern.

- Dual Rack and Pinion Gate prevents jams.

- Overhead spinner motors are ABOVE the chemical resulting in extended motor life.

- Pull with a tractor, no need to maintain a dedicated chassis and power train.

- Variable or straight rate compatibility.

- UHMW precision-cut comb cover prevents spillage of fertilizer and potential streaking in the field.

- Flotation tires and wider swaths minimize compaction.

- Standard chain option spreads lime up to 2 tons per acre @ 14mph with a 60′ swath.

- Spreads fertilizer in 80′ swaths.

- Add Javelin Spinner Assembly to Spread Fertilizer 120′ with a single pass (not for use with lime).

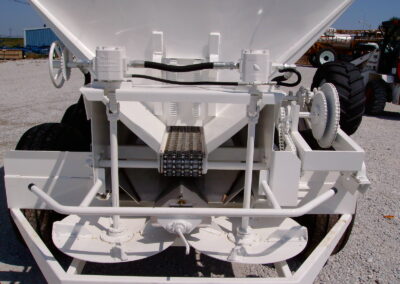

BBI Liberty & Trooper 8 Ton Spreaders

Liberty & Trooper Tandem Axle Fertilizer Spreader. Fertilizer/Lime Spreader. Available in 409 & 304 stainless steel. Heavy Duty Tandem Axle, with standard or flotation tires. Hydraulic-driven spinners and ground wheel drive conveyor. Conveyor available in 20″ & 16″ width stainless steel mesh chain for a combination Fertilizer/Lime Spreader or an 8″ stainless steel mesh conveyor chain if you are only interested in a fertilizer application. Both the Liberty and Trooper Spreader have an 80 ft. spread pattern with most granular fertilizers. THAT’S RIGHT AN 80FT. SPREAD PATTERN!

That 80ft spread pattern is easily adjusted via the manual crank that adjusts the flow divider in and out with an easy to read flow divider gauge and pointer. This adjustment moves product in and out in the pattern to fine-tune your pattern and product coverage. Then you just adjust the spinner RPM via the tractor hydraulic flow or manual adjustment on the spreader to increase or decrease your spread width. It’s super easy!

Standard BBI Liberty Spreader Options

- Bearing backers keep bearings clean, giving longer life and fewer failures.

- The proprietary system delivers a wider, flatter, more consistent pattern.

- Dual Rack and Pinion Gate prevent jams.

- Overhead spinner motors are ABOVE the chemical resulting in extended motor life.

- Pull with a tractor; no need to maintain a dedicated chassis and power train.

- UHMW precision-cut comb cover prevents spillage of fertilizer and potential streaking in the field.

- Standard chain option spreads fertilizer or lime.

- Spreads fertilizer in 80′ swaths.

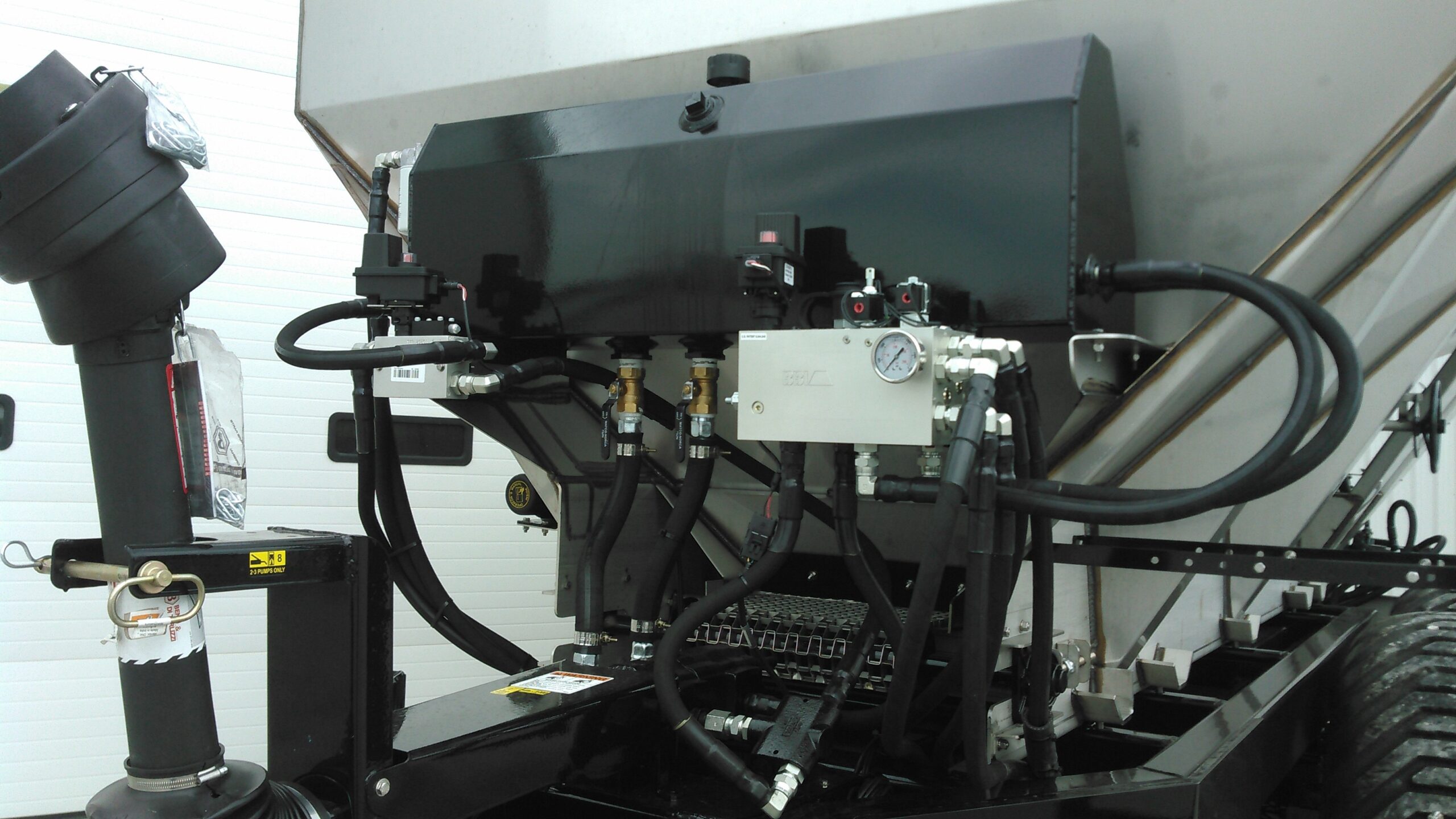

Variable Rate Compatible Liberty or Trooper

The BBI Liberty model spreader has always been a great performer in the field with an 80 ft. spread pattern and available in a standard fertilizer only or combination configuration to spread both blended fertilizers and lime. Brothers Equipment can enhance the possibilities of the BBI Liberty or Trooper product models lineup by adding an ISO Rate Controller with a PWM valve, sensors, and all the cables. This is also a Brothers Equipment Exclusive.

The Liberty/Trooper VR is Available in 3 Rate Control Configurations

- The very popular ISO plug to tractor configuration allows you to plug directly into your JD or Case Tractor ISO plug and control the spreader with your JD2600, JD2630, or the Case Pro700 and other ISO compatible displays. This is a fantastic way to take advantage of your current VT display.

- Raven SCS660 Dry rate controller. This option allows you to run the spreader with the Raven SCS660 and apply a straight rate with speed changes. The Raven SCS660 will adjust and apply the programmed rate with ground speed variations. With this option, a Raven Cruizer II or other guidance could be used to ensure proper driving and coverage.

- Raven CAN product control is used in conjunction with the Raven Viper, CR7, CR14, or SCS5000 rate controller.

Call us today to inquire more about the Liberty VR at 800-228-4582

New Scale Installation on Liberty and Trooper Spreaders Available

This is a Brothers Equipment Exclusive. Scale options for Liberty and Trooper models are not available from the Factory. Give us a call, and we can give you information and pricing on the scale option.

Grasshopper10 Single Axle Row Crop Spreader

10’ Salford/BBI Single Axle Grasshopper10

Hydraulic Fertilizer/Lime Variable Rate Precision Application Spreader. Available in Mild Steel, 409 Stainless Steel, and 304 Stainless Steel. ISO Bus Ready Spreaders can be operated with your Current ISO Variable Rate Terminal (JD2630, Case Pro700, and others)

Standard BBI Magnaspread Spreader Options

- UHMW bearing backers keep bearings clean, giving longer life and fewer failures

- Proprietary MagnaSpread system delivers a wider, flatter, more consistent pattern.

- Dual Rack and Pinion Gate prevent jams.

- Overhead spinner motors are ABOVE the chemical resulting in extended motor life.

- Pull with a tractor; no need to maintain a dedicated chassis and power train.

- Variable or straight rate compatibility.

- UHMW precision-cut comb cover prevents spillage of fertilizer and potential streaking in the field.

- Standard chain option spreads lime up to 2 tons per acre @ 14mph with a 60′ swath.

- Spreads fertilizer in 80′ swaths.

- Add the Javelin Spinner Assembly and Spread Fertilizer 120′ in a single pass (not for use with lime).

BBI Endurance

Litter, Lime, Shavings, and Compost Spreader

The BBI Endurance Hydraulic line of litter/lime/compost spreaders is available in pull-type and truck mount models and designed to be the toughest, most durable spreader equipment on the market today. Endurance hydraulic models are equipped with the NEW BBI Binary Manifold and are ISOBUS ready for the latest in control and guidance systems. The Endurance™ Pull Type Hydraulic series-wide swath litter/lime/compost spreader is designed with the grower in mind, while farmers appreciate the rugged design of the lime and shavings spreader. With BBI’s robust design and construction, you can more efficiently spread your materials, saving you time and money.

BBI Endurance Options

- BBI Binary Manifold STANDARD for quick install of ALL precision agriculture tools.

- Bolt down hoppers standard on all spreaders

- UHMW and stainless steel reduces corrosion issues and extends the life of the spreader.

- UHMW bearing back keeps bearings clean, resulting in longer bearing life and fewer failures.

- Optional UHMW poly floor lasts the lifetime of the spreader. The drag coefficient is less than steel. Hydraulics run cooler and last longer with less stress on the system. Floor chain, motors, and gear cases last longer.

- 3/8″ Fin – 33% thicker than traditional designs.

- Dual Rack and Pinion Gate prevent jams.

- Flotation tires minimize compaction.

- Innovative spinner motor eliminates motor failure at the pressure seal.

- HD two-section pumps run cooler and last longer.

- Fuel and time to apply are reduced by 50%.

- Lower maintenance expense.

BBI MangaSpread 2 and MangaSpread 3

MagnaSpread2 Pull-Type 2-Bin 00MS2P

With BBI’s patented multi-bin technology, the MagnaSpread 2 pull-type features two hoppers guided by independent variable-rate technology. MagnaSpread 2 gets a dry application of fertilizer and lime done faster and more efficiently.

MagnaSpread3 Pull-Type 3-Bin 00MS3P

With BBI’s patented multi-bin technology, the MagnaSpread 3 pull-type features three hoppers guided by independent variable-rate technology. MagnaSpread 3 offers the most sophisticated multi-nutrient application on the market.

SPINNERS: MagnaSpread system standard. Overhead spinner motors are also standard.

ELECTRONIC CONTROL: Electronics for variable rate control and guidance are included in the list price. Please contact BBI for more information.

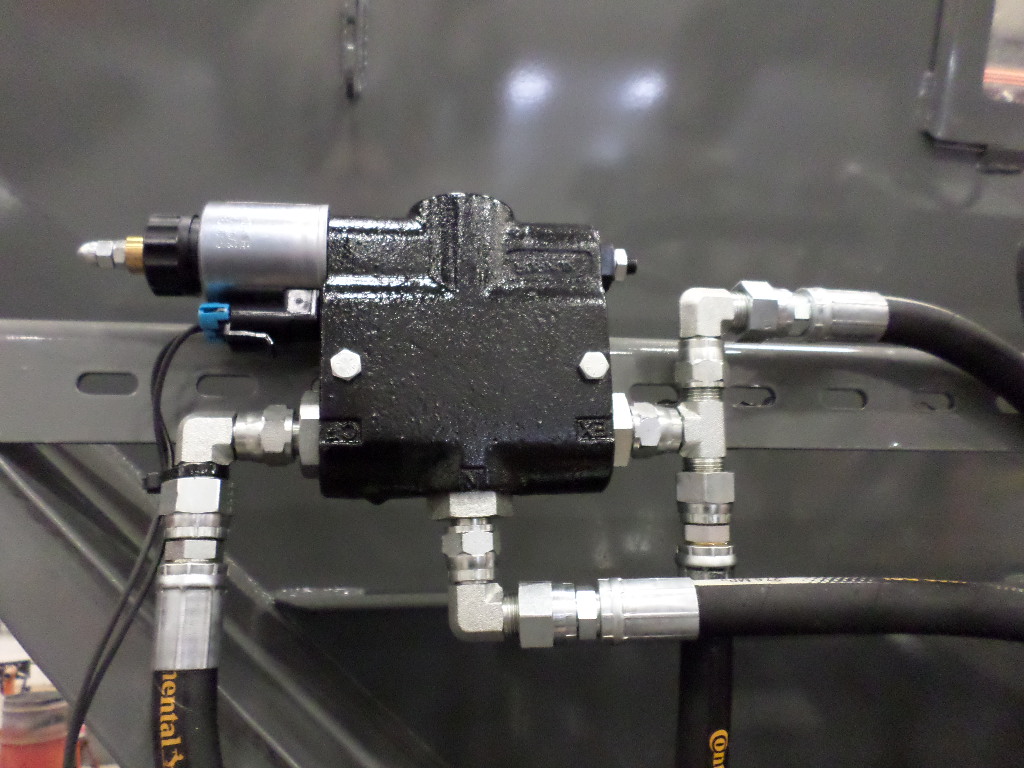

BBI BINARY TM HYDRAULIC MANIFOLD SYSTEM for MagnaSpread 2 & 3: Combines the hydraulic controls for the conveyor and spinners into one control manifold. It includes proportional manual speed control for both spinners and conveyors. Pilot operated relief is standard. A dump valve and a GR is standard for the conveyor. The BBI Binary Manifold modularity allows for quick, easy conversion to GR option and electronic control.

14 TON WALKING BEAM HEAVY DUTY SUSPENSION (21.5L 14 Ply Tires and 10-Bolt Hub): Includes CV Joint PTO Shaft Series 6, Heavy Duty Jack, and Large Perfect Hitch. (Pintle and Clevis). Larger flotation tires are available as options.

MagnaSpread3 was previously named Triad.

Salford/BBI Single Axle Magnaspread + Plus

The future of nutrient application is here…

The MagnaSpread Plus uses tried and tested hopper designs, the high-clearance single axle 12 foot hopper or the tandem axle 20 foot hopper, equipped with Salford BBI’s latest advancements in application technology. Engineering improvements make this spreader even more accurate and easy to set. The axle configurations help producers who need the widest application window or those looking for the maximum pay load.